Changemakers: Fyrn

13-Feb-2024

Fyrn’s Keyhole table, Mariposa chair and Shorty chair

‘Great design considers future circumstances’

FYRN believes every part should be replaceable, and flat packs high-end furniture.

Interview #6 in the Changemakers series

In this interview with David Charne, co-founder and CEO of Fyrn, we explore the approaches to hardware, packaging and waste-reduction – and great aesthetics – that define Fyrn’s circular business model. They’re determined to keep their furniture in circulation for the long run.

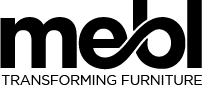

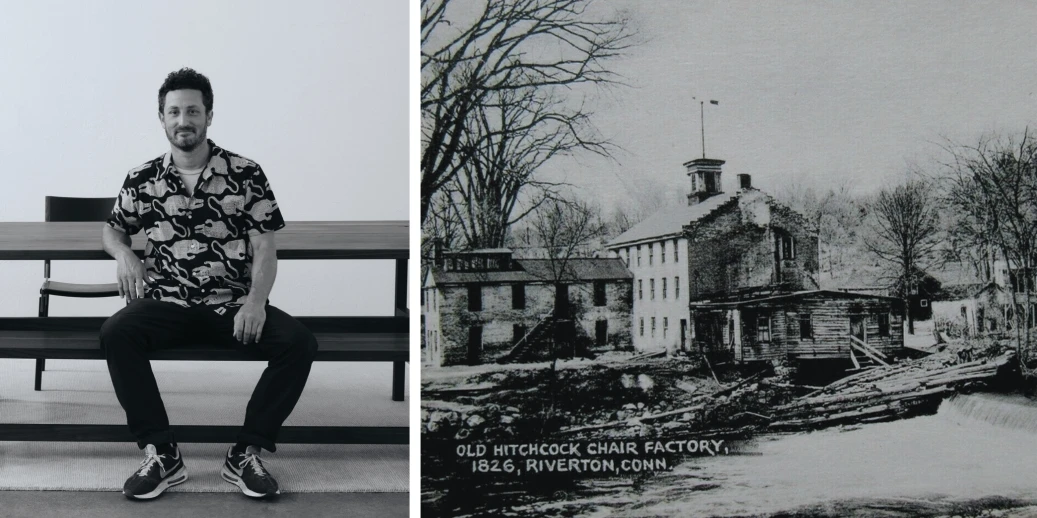

Charne, along with Ros Broughton, co-founded Fyrn in 2016 as a descendent of the Hitchcock Chair Company, which first opened in 1818 and is one of the oldest chair producers in the United States. Ros grew up learning from his granddad - Hitchcock’s head of production - about the challenges of servicing, warehousing and distributing furniture.

Charne and Ros set out to build on those lessons, “exploring inventive ways to bring availability and scale to high-end craftsmanship-grade furniture” – all while committed to circular practices. Today, Fyrn is a 20-person operation with prototyping facilities in San Francisco and production in Nevada.

This is the 6th in our Changemakers series – interviews with leaders in sustainable, circular and regenerative approaches in the furniture industry. Our aim is to uncover the nuts and bolts of how each leader is driving change, the potential it holds, and why it matters to the industry.

Left: David Charne, co-founder and CEO of Fyrn. Right: Old Hitchcock Chair Factory in 1926

mebl: We love Fyrn’s essential commitment to a more circular economy. How does your furniture embody circularity?

David: We design and build around a system-of-furniture we invented called Stemn. This hardware system reflects our belief that every part in a piece of furniture should be replaceable, quite simply and quite easily. This system consists of custom-designed joints and locally-sourced hardwood.

Every piece of Fyrn furniture can be readily assembled and disassembled. So it is easily repaired, creating the possibility that it could last forever! Fyrn furniture also focuses on enduring – not trendy – design, making our products desirable for longer.

In production, we have very little excess material. Less than 10% of the North American hardwoods we use to produce seating gets wasted. And what doesn’t get used gets composted. For the hardware, we use milled anodized aluminum and steel that can be recycled back to its raw material.

mebl: How did you invent the Stemn system?

David: Starting around early 2012, Fyrn’s co-founder Ros Broughton, along with Derek McCall -- who now leads our product development – started experimenting on what-became 50 iterations of the Stemn bracket. Of particular design importance was how the wood would integrate into the metal. They wanted to minimize material use to make the furniture as lightweight and mobile as possible.

In 2014, Ros sent functional prototypes of early Fyrn chairs to some friends’ San Francisco restaurants to test their durability in a high-traffic environment with heavy use and abuse. Many of these chairs are still in use today! In these restaurants, we were thrilled as people began to flip the chairs over to check the brand.

Fyrn’s Stemn bracket and how it’s used in a Fyrn dining chair

mebl: How does Fyrn further minimize waste?

David: We have a second-hand platform on our website called Annex. Through it, we’re able to intake used furniture and parts, refurbish them, and still make a profitable sale. Beyond reducing waste, this buy-back initiative has a second benefit - offering a better price point to individuals that want to own a Fyrn piece but can’t yet afford it out-of-the-box. In addition, rather than discarding any raw material components that are aesthetically imperfect, we use them to produce 2nds furniture, also for sale through the Annex.

In production, we cut down on waste by taking wood with too much sap or blemishes and coloring it to charcoal black. Although we rarely put color on our furniture, black is consistently in demand and has proven to be a great circular solution. By thinking systematically about our market offering, we’ve managed to reduce waste of raw materials.

We’ve also been mindful of waste at an organizational level. Often, valuable time and energy is lost when someone interrupts your deep work pattern to ask a question, or with unproductive movement around a facility. Inspired by a prospective vendor, we’ve started exploring and implementing systems that optimize human efforts and use previously lost time for problem-solving.

Charcoal black is a popular finish, and creates an opportunity to reduce waste by giving Fyrn a way to use heavy sapwood or hide other natural blemishes.

mebl: What’s a challenge you’ve faced in applying circular-design thinking?

David: We wanted a higher-quality screw that omitted the need for a spacer and was manufactured domestically. Not only to save money, but to simplify the process of assembly for our customers. Although a screw is a small component, we saw an opportunity to improve our design and secure a domestic material source. Without originally intending to, we ended up designing and manufacturing our own custom screws! It was a long and complicated process – some argued a waste of time! – but in the end it was well worth the effort.

mebl: Is there another example of a circular initiative that was challenging?

David: This one is about psychology! Our furniture ships flat. It comes semi-assembled in a beautifully designed box. In the commercial furniture space, industry standard is for high-quality items to arrive fully assembled. In customers’ minds, there’s often a lower perceived value to products that arrive requiring assembly.

It’s taken a while for our clients to understand two things – first, how easy it is to assemble our furniture. And second, that, through flat-packing, we are saving substantially on the costs associated with moving and warehousing heavy furniture – and we’re rerouting these savings into better prices and making even higher-quality furniture.

We can ship six chairs in the space of one fully-assembled chair, and we don’t need any plastic to protect them. Not only does this lower the carbon footprint, but we can move our products more quickly and cost-effectively with a better level of service. We hope our success will inspire big manufacturers to rethink their offering and ‘knock down’ their furniture into smaller, manageable parts. It’s the kind of change we hope to spark.

Fyrn furniture components, disassembled and stored

mebl: Are there additional changes you’d like to help spark across the furniture industry?

David: Here are a few of Fyrn’s principles we’d encourage across the industry. We like to say that great design considers future circumstances. It’s every producer’s responsibility to think about design holistically and consider a product’s full life cycle. What good is it to achieve a zero-waste facility but make furniture that's gonna break in three years?

Brands need to be thoughtful about treating their customers as partners, not opportunities. And we’d love to see greater accountability and transparency in companies’ sustainability commitments - especially how progress is reported. False claims and misinformation must be curtailed.

We rarely see sustainability as the primary driver of purchase decisions - that still relies on good design, aesthetics and price point. To ‘sell’ sustainability or circularity, there has to be a financial benefit for people to adopt it. In the bigger picture, government could certainly encourage domestic manufacturing to create more jobs and careers. Innovation and ‘solution creation’ should be incentivized to drive industry change.

mebl: What’s your next circular frontier?

David: We’ve been playing with adding tables, lounge chairs and couches to our product offering -- but these are more challenging pieces to make circular. We’re debating whether we simply don’t offer these products, or if we should add them with an acknowledgment that we don’t have the perfect solution.

We would make cushions that can be reupholstered and replaced, but ultimately soft goods won’t last forever. For dining tables, we’re designing a system that allows for disassembly, but it’s not easy. Bottom line, with every new product line, we consider where we can have the biggest impact and try to improve it with time.

Fyrn’s classic chairs, backless chairs, and counter and bar stools.

READ more Changemaker Interviews here.