Changemakers: Gensler

05-Dec-2024

We sat down with Sarah Templin to learn how Gensler sees its Product Sustainability Standards as an opportunity to collaborate with manufacturers to define a healthier future for our industry. As Gensler is among the largest architecture firms in the world, beginning to hold its suppliers accountable to product standards holds the potential to drive meaningful change in sustainability across supply chains.

Interview #10 in the Changemaker series

Gensler’s standards are part of a company-wide commitment to carbon neutrality by 2030. “We need to act swiftly, with determination, and with big ideas now,” urges Templin, who, in her role as Sustainable Materials Specialist, continues to engage her forever passion for rolling up her sleeves to work with manufacturers, on manufacturing.

This is the 10th in our Changemakers series – interviews with leaders in sustainable, circular and regenerative approaches in the furniture industry. Our aim is to uncover the nuts and bolts of how each leader is driving change, the potential it holds, and why it matters to the industry.

Sarah Templin

mebl: Hi Sarah! Tell us about your background, and how you landed in the design and furniture industry.

Sarah Templin: I have a longstanding passion of working with manufacturers. I started out launching a textile design company that manufactured upholstery-grade textiles in the US. That evolved into making homegoods. I then went to graduate school in industrial design, which led me back to working with manufacturers – this time to help them redesign their products for the circular economy and other sustainable goods.

Simultaneously, I was teaching product design at Parsons School of Design and at the Maryland Institute College of Art. This offered me the opportunity to engage with students. We would experiment on developing concepts that could then be tested in the field with clients. My work with students and with clients really fed off of each other symbiotically.

mebl: How did this lead to your current role at Gensler?

Sarah Templin: A little over a year ago, I started working at Gensler as a Sustainable Materials Specialist and the Manager of the Gensler Product Sustainability Standards.

In this role, I still get to interact with manufacturers daily. This is really satisfying for me because there's so much potential there — often, for example, we map out simple design changes that can significantly improve the sustainability of products.

mebl: Has sustainability been your personal defining mission since day one?

Sarah Templin: Several years ago, I faced a conflict as a product designer. I enjoyed knowing how things came together, but I was at odds with myself about participating in continually making more stuff. I didn't want a life doing that — it would’ve sent me into an existential tailspin!

I don't consider myself a science person. But I see sustainability as the topic of my era. There’s a void there, and I could easily jump into it. I want to participate in product design, but it’s clear we need to prioritize sustainability.

Whether you see yourself as a specialist, or an advocate, or sustainability has always been your passion – the time is now to pay attention. It’s an undercurrent in everything. We can’t wait any longer.

mebl: What’s the role of Gensler in the industry?

Sarah Templin: Gensler is among the largest architecture firms in the world, focused on interior design and architecture. As such, each year we specify a huge volume of product purchases. And we take very seriously the responsibility that comes with that. With 57 offices across the world, our sustainable policies, supply chain, and criteria span the US, Canada, European Union and the UK.

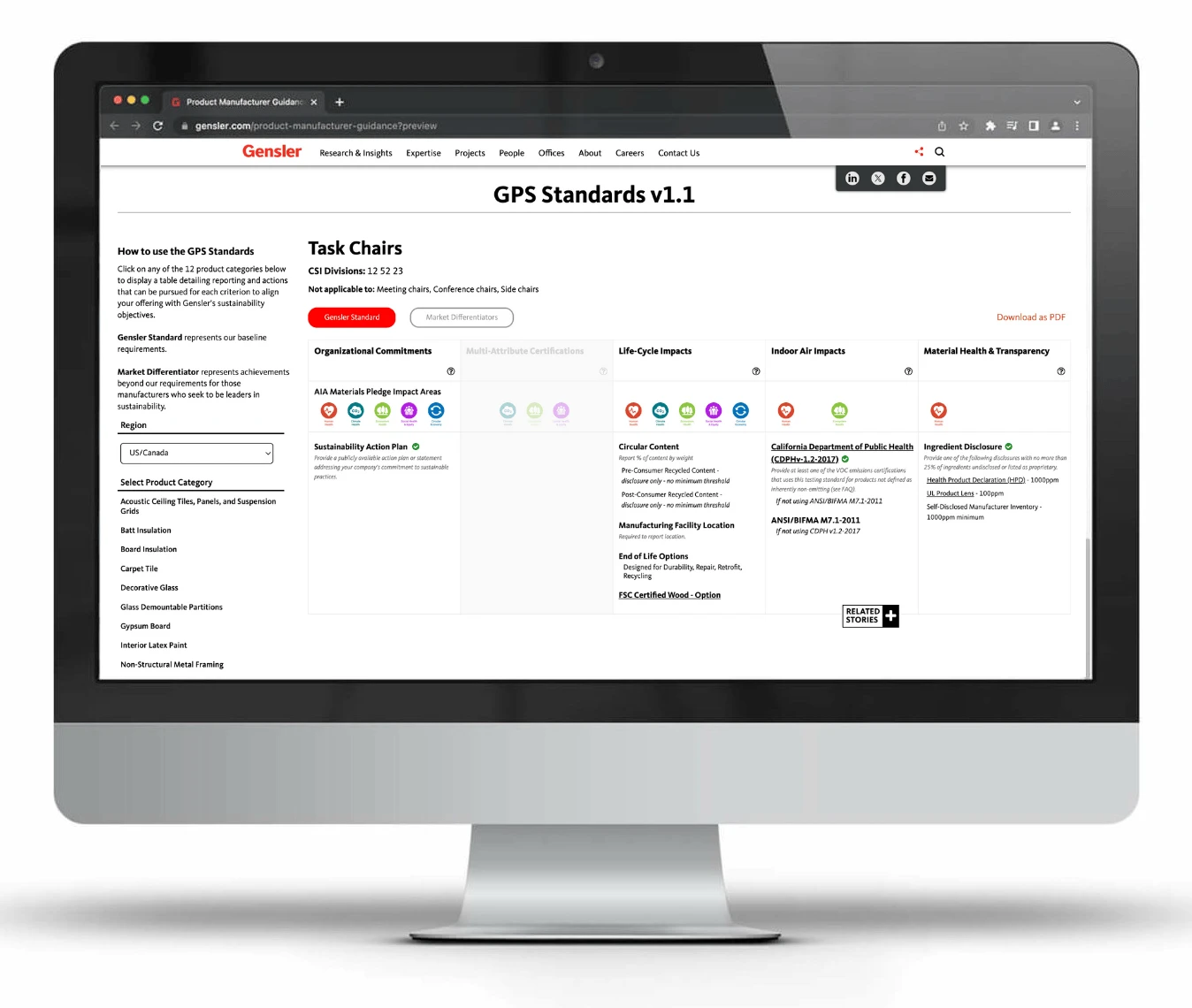

I manage the Gensler Product Sustainability Standards — which we call GPS. This is a set of holistic sustainability criteria spanning five impact categories. Currently, we have sustainability criteria for 12 varying product categories, two of which are furniture related — systems furniture and task chairs. Examples of other product categories, to name a few, include board insulation, carpet tile, and decorative glass.

We just launched draft criteria for an additional eight product categories, including textiles, tiles, and broadloom carpet. These are set to be solidified by January 2025. We're currently soliciting feedback on the new categories — so when we issue its criteria, we're doing it in collaboration with the industry.

mebl: Would you say that's reflected in what Gensler is doing now – moving sustainability to the mainstream of industry standards?

Sarah Templin: At Gensler, our goal for every project is to have strong sustainability criteria that are measurable and actionable.

In 2019, Diane Hoskins– then co-CEO of Gensler and now the company’s co-chair of the board – made a promise at a United Nations forum that the company would become carbon neutral by 2030. This meant both reducing operational and embodied carbon on projects, as well as reporting on that carbon. Part of the goals for GPS is to be a roadmap for reducing the embodied carbon on our projects.

We've already had many manufacturers adjust their processes, ingredients, supply chain, etcetera, in order to meet our standard level. In fact, many have said that the GPS validated things for them. It wasn't until there was a strong market signal coming from the industry that they felt they had the support needed to pursue these sustainable practices.

Diane Hoskins — then co-CEO of Gensler and now the company’s board co-chair –

made a commitment in 2019 to company-wide carbon neutrality by 2030

mebl: Earlier you noted that minor design changes in products can have significant sustainability impacts. Can you give an example?

Sarah Templin: One poignant example was when I worked with a client to remove adhesives from their furniture — which are toxic for manufacturers and toxic in our homes. Adhesives also make reupholstering a piece of furniture much more labor intensive, thus reducing its life cycle.

With manufacturers, we would discuss how we could attach cushion frames in a way that doesn't use adhesive, then analyze which options we could scale. With my students, I encouraged them to try new methods — and consider how the design or aesthetic of a product could shift based on new techniques they were developing.

Eventually, these considerations carried over to senior thesis projects, which then carried over into careers. In this way, those seemingly simple exercises could have a really big influence. It taught me that a great way to make an impact is to train new generations of designers to be more mindful in their choices.

At Gensler, since launching GPS, we've trained our designers to request Environmental and Health Product Declarations (EPD’s and HPD’s) from manufacturers. Designers need to learn how to read these documents; and how to move conversations with sales reps on these issues.

This way we can all make educated choices…without having to dig through all those unclear marketing pamphlets!

mebl: Let's go back to the standards. What exactly are they and what inspired their launch?

Sarah Templin: It's rooted in Diane Hoskins’ UN declaration that I mentioned earlier – committing Gensler to carbon neutrality by 2030.

While we were already reducing our operational carbon impacts, we needed a plan to reduce embodied carbon. A Gensler team began by identifying which product categories we specify the most; which of those have a high carbon impact; and which already have industry-wide data available.

Our next step in developing our playbook was to begin to draft our own criteria in tandem with third party certifications such as the AIA (The American Institute of Architects) material pledge, Cradle to Cradle, BIFMA (Business and Institutional Furniture Manufacturers Association) and other certifying bodies.The criteria is designed to be a holistic examination of a product, with requirements around life cycle impacts, indoor air impacts, material health and transparency, and organizational commitments. We began to meet with manufacturers who develop the products we specify most frequently to solicit feedback on if they could meet a range of these standards. It was a very collaborative process.

The result is our Gensler Product Standards — a list of 12 product categories created based on existing criteria – which currently have the highest carbon output and which we specify the greatest quantities of. We feature two levels: our baseline criteria – called standard – that all Gensler-specified products need to meet. And then there’s the market differentiator level, a more ambitious criteria for products at the forefront of the sustainability movement.

To ensure we're all on the same page, our criteria align with mindful MATERIALS’ common material framework (also known as CMF) — a universal baseline of definitions for sustainability terms and expectations. CMF also focuses on separate “impact categories,” and is, all in all, a central part of the architecture and design industry. Which is why it’s key that our criteria align.

A closer look at Task Chairs, one of 12 product categories

as specified by the Gensler Product Sustainability Standards

mebl: What is the dynamic between standard and market differentiator criteria? How does that work internally, in terms of what you specify or recommend? What if a Gensler client has a favorite supplier who doesn't meet GPS standards?

Sarah Templin: We work with our manufacturers to see which standard level their products meet. They submit data to us on all their products. If something doesn't meet our standards, we work together to help the company achieve compliance.

It’s crucial we share information from our manufacturers, with our designers. Which is why transparency is necessary. This way, our designers also have access to the information and can review the data of products. If their products don't meet the criteria, they can see why. And if they really want to specify a product that doesn't meet the standard level, odds are we're already working with the manufacturer to get them compliant.

Many of us at Gensler and in the industry genuinely have shared goals and want to support each other in reaching them.

Gensler’s project at St. John’s Terminal, Google’s newest NYC offices —

which the company flags as saving 78,400 metric tons of CO2 emissions;

incorporating 1.5 acres of native landscaping; and creating new habitats for the local ecosystem.

mebl: And how does that spirit of “let’s move forward” work with other big architectural firms, or with specifiers in the industry?

Sarah Templin: That's where the CMF really comes into play.

Both the Common Materials Framework and Gensler's criteria are publicly available. This way, anyone can see exactly what the criteria is, as it is being published in real time. Any manufacturer can see what our baseline is and where we think the industry is going – as reflected in the market differentiator level. All architecture firms and designers have equal access.

We’re a big company, which means we have the resources to gather data, as well as an interest in sharing it. Anyone can access our criteria – adopt or steal them, do whatever they want! Or entirely lift them off of our website. We encourage it!

mebl: Is there industry competitiveness around standards?

Sarah Templin: What we’re ALL really competing against is the climate clock. We just had an in-person three-day work session in Minneapolis with several dozen other companies. It took place at the same time as the pair of unprecedented hurricanes across the southeast US. The intensity of those climate events solidified the reality that time really is of the essence. We need to act swiftly, with determination, and with big ideas now. And that’s a major motivating factor for all of us, I think.

We don’t necessarily have internal industry conflicts, but there are what feel like ‘existential threats’ at play. At times you wonder if you are choosing one type of sustainability criteria at the expense of another. Our criteria make it very clear that one cannot choose reduced carbon goals at the expense of material transparency or other sustainability criteria. It must be a holistic examination that takes all of these issues into account.

mebl: Are there furniture categories you hope to add to the Gensler standards in the near future, in addition to the two current categories – task chairs and systems furniture?

Sarah Templin: We specify a much higher quantity of task chairs and systems furniture than any other furniture category. Our priority is criteria for product categories where we can have the biggest impact first. That’s why we focused on those two initially. For those less familiar with the term ‘systems furniture’ — this is defined as a panel-based workstation composed of modular interconnecting panels, or a freestanding grouping of furniture designed to work in concert to create a workstation.

These categories are also primarily manufactured by large corporations, which means they have the budget to do VOC (Volatile Organic Compound) testing, EPD’s, HPD’s, etcetera. When we get into ancillary furniture, it’s more likely we're dealing with smaller companies.

We don't want our criteria to become existential threats for smaller companies. Our new product categories, for example, include textiles and wallpaper — sectors with numerous smaller companies. We're very sensitive to issuing something like a required EPD – we don't want to require a small company to make $15,000 investments for each line of wallpaper. That's not realistic, and not a fair expectation.

Which is to say – we tread lightly. We're mindful of who we work with and of issuing criteria that are realistic. We don’t want to circulate something that can't be implemented.

Examples of the 12 product categories specified under

the GPS and the spaces in which you may find them

mebl: What excites you most about the standards’ next steps?

Sarah Templin: I’m particularly excited about two things — and both tie back to my personal history.

One is the educational component. We don't want anyone to ever feel intimidated. So that means making sure both designers and manufacturers feel confident in the data we’re presenting — in discussing it with other industry participants, in knowing how to use and talk about it, and in optimizing their designs around it.

I’m also excited about our continued collaboration with manufacturers — looking at products, considering roadblocks, and working together to solve them. It’s a process I enjoy and luckily a big part of working in GPS.

As for the future — I’m very interested in getting deeper into supply chain transparency and circularity. Both arenas could use more pilot programs, more case studies and further examination so that we can figure out how to meaningfully implement.

mebl: Could you take it a step further — what do you mean by supply chain transparency and circularity? What's the challenge there?

Sarah Templin: Supply chain transparency is consistently difficult for manufacturers, no matter the size, location, or product category. We'll ask manufacturers for information that they themselves have a hard time tracking because supply chains are so long and convoluted. They’ll try to trace it back, but things quickly get muddy.

This brings to light important questions regarding carbon footprint and forced labor — more prevalent than most realize and part of what’s so difficult to track. A lot of companies will require documentation on labor practices in the near future. There's some software out there for this already, such as Design for Freedom, but it’s difficult to scale, leaving room for growth.

Circularity, on the other hand, can be hard to make work financially. And we need transparency here too. What percentage of products are taken back via take back programs? Are they going directly back into product lines? Or are they being down cycled into something else?

We have to wonder — what is really happening in practice and how are we going to scale this to make it work?

READ more Changemaker Interviews here.