Changemakers: Meno Home

22-May-2025

Jerri Hobdy, founder and principal designer at Meno Home, believes in combining creativity, pragmatism and persistence to change an industry — not just products. From Cradle to Cradle-certified prototypes to commercially scaled collections, Jerri Hobdy is showing that cleaner, healthier, lower-impact materials are not only sustainable but make good business sense.

Interview #12 in the Changemaker series

In this interview, we talked about redesigning Dunbar Furniture's iconic 5407 Party Sofa with low-impact materials, Jerri's college thesis, and the role of data in evolving her theory of change.

This is the 12th in our Changemakers series – interviews with leaders in sustainable, circular and regenerative approaches in the furniture industry. Our aim is to uncover the nuts and bolts of how each leader is driving change, the potential it holds, and why it matters to the industry.

Jerri Hobdy

Photography by Sara Ford Photography.

mebl: Tell us about yourself and what sparked your journey into sustainability? Would your 5th grade teacher be amazed by what you're doing today?

Jerri Hobdy: I don’t think she would be surprised! She would say “Jerri tinkers a lot and likes to make things with her hands.” But my interest in science might be a little surprising to her!

Right out of the gate – since studying furniture and lighting design at the Savannah College of Art and Design – I’ve been interested in material health. It falls under the umbrella of sustainability and has a huge impact on people and resources.

This inspired my senior thesis project – what it takes to make residential furniture achieve Cradle to Cradle certification. I then submitted my project to the Cradle to Cradle Institute’s first-ever global design competition. And I ended up winning in the global professional category! It was very validating.

mebl: Amazing winning that award right out of college! So, for a moment, jump ahead to the present.

Jerri Hobdy: I launched Meno Home at the end of 2021. Our focus is on moving the needle in sustainability within the built environment – through furnishings. Our motto is “Designing Furniture, Building Change.” We emphasize waste reduction, climate-friendly materials, removing toxins, and lowering the carbon footprint in furniture logistics.

At the start, our focus was on vintage furniture. It was a cost-effective way to get off the ground — I could source inventory affordably. Each time we reupholstered a furniture piece, or replaced foam with natural latex, it was a step forward in proving that cleaner, healthier choices could be both viable and profitable. I found, for example, that our refurbished vintage pieces sold for an average 90% margin, compared to 70% for new furniture.

Over time, MENO has evolved into an incubator for change. I design furniture for major brands, seeking to influence industry standards from within, while simultaneously building a clear model through MENO. I continue on two tracks – growing MENO as a retail brand with different product offerings, and positioning MENO as an incubator for testing different sustainable methodologies, product types and materials.

This has spawned many fruitful collaborations. One example is our work last year on the Dunbar sofa. Now, in 2025, we’re launching our own commercially-scaled furniture line, taking MENO’s sustainability vision even further.

mebl: Tell us about remaking the Dunbar sofa.

Jerri Hobdy: Last year was the 70th anniversary of Dunbar Furniture’s classic 5407 Party Sofa. In all those decades, nothing about the design had changed. I shared my theories on sustainability with Andy Heiser, the president of Dunbar, and he immediately saw the value of a remake. We rebuilt this sofa with new clean materials, a new recipe in a way. We literally swapped out the conventional materials for new materials.

As this was already a long-time, successful sofa design, the variable of aesthetic appeal was removed. This really gave us a chance to ‘test the recipe’ for the appeal of cleaner materials in furniture, and then test how we share information about that recipe. The sofa looks and feels identical, but the impact of the materials that we're using is dramatically improved.

For example – we have removed polyurethane foam (conventional foam) which is petroleum derived. We have also ensured that there are no harmful PFAS (forever chemicals) or flame retardants being used on our foam or cushions filling. We're trying to figure out how to communicate this difference without greenwashing. That's where data comes in.

mebl: What was most challenging about the Dunbar Sofa redesign?

Jerri Hobdy: Ensuring the sit. This is a pretty iconic piece. Great design aside, this sofa is timeless because it feels good to sit in. This is a recurring concern I’ve heard from multiple clients — concern that any change in material might compromise the signature comfort their customers expect. With the Dunbar sofa, this was a critical, yet invisible, factor we needed to solve for.

Through trial and error — almost like pseudo-engineering – we experimented with layering different materials as substitutes for polyurethane foam. First, we tested various thicknesses of latex combined with Cocolok, a coconut fiber byproduct. Cocolok has more spring-back than latex alone, which primarily compresses.

The challenge was to replicate the Dunbar’s bounce without relying on steel springs, which would complicate disassembly at end-of-life — for true circularity, every choice matters. After trying different combinations, we eventually found the best solution — thin layers of latex sandwiched between multiple layers of Cocolok. This approach maintained the desired comfort and resilience but also helped us with cost, as latex is about three times more expensive than polyurethane foam.

Having a willing corporate partner made all the difference. The Dunbar workshop team was open to testing, tweaking, and giving real feedback. That hands-on approach helped us refine the design efficiently without overcomplicating it.

The Dunbar Sofa by MENO Home

mebl: Can we go back to your senior thesis project? That was really interesting. You built an actual product?

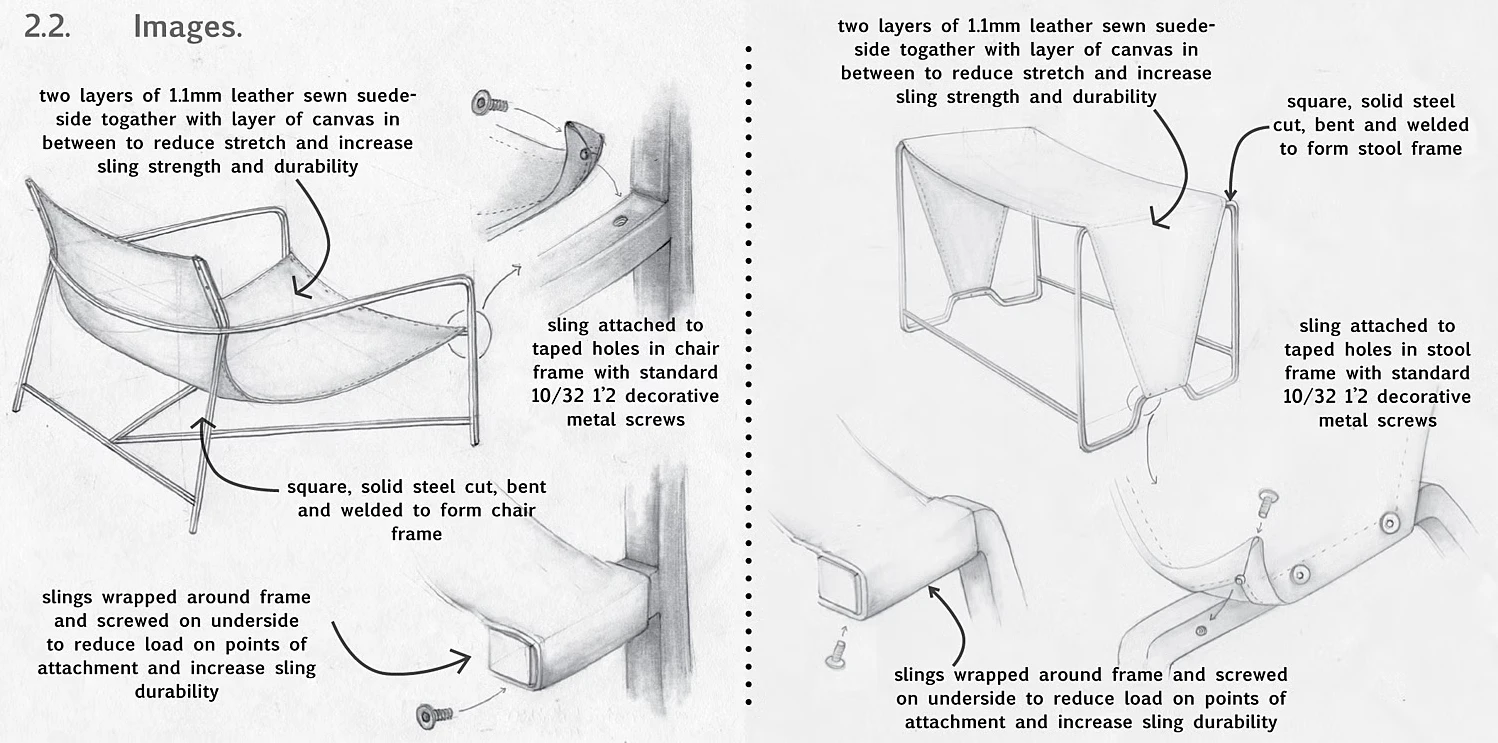

Jerri Hobdy: Yes, it was a leather sling chair with a steel frame and matching ottoman. Reminder that I was looking at what it would take to make residential furniture achieve Cradle to Cradle certification. In my sling chair, I used Moore and Giles’ Virginia vegetable tanned leather, which was their greenest option at the time. They were kind enough to donate it to me as a student.

Then I examined how to make steel cleaner from an end-user and worker perspective. Steel has a high embodied carbon as it is carbon intensive to make. It also can be treated or coated in chemicals that help resist corrosion but oftentimes those are not the safest coatings for workers / fabricators or manufacturers. So, in seeking a durable, rust-resistant finish without using harmful chemicals, I ended up using a beeswax and oil combination after heating (or burnishing) the steel to remove moisture from the pores.

I designed pieces that removed the foam, because I wasn't really aware of alternatives for the fill at the time. I focused on reducing the design to its simplest and most necessary components, and then figuring out the better substitute for the materials.

Image courtesy of Cradle to Cradle Products Innovation Institute.

The Pure If Hide chair prototype uses two layers of 1.1mm leather sewn together with a layer of canvas sandwiched in-between. This reduces stretch while increasing strength and durability.

mebl: What was your central hypothesis?

Jerri Hobdy: I wanted to show that there were already scalable materials on the market – largely for commercial use – that could be swapped in to help residential furniture achieve Cradle to Cradle certification. Steelcase had made significant progress in the contract and commercial sectors, but this concept was virtually absent in residential furniture. There were a few outliers, like Cisco, and select leather suppliers such as Edelman and Moore & Giles.

Ultimately, it was about market viability — why can’t we substitute better materials today while still delivering the aesthetics customers want, the durability they expect, and the heritage materials they trust? It all tied back to what I learned in design school: creating desirable products.

mebl: Eleven years later, where do you see the most progress ?

Jerri Hobdy: Definitely in material innovation. That’s where most new tech startups adjacent to manufacturing are focused, and that’s where I’ve seen the most investment, improvement, and fresh ideas. The Mycoworks Reishi mushroom leather and Sway’s Seaweed Packaging are good examples.

Meantime, core manufacturing techniques used to assemble furniture haven’t changed much, but some operational aspects have improved — for example, the manufacturer we work with in India now operates a solar-powered facility.

mebl: What happened next? And has your theory of change evolved over time?

Jerri Hobdy: Right after college, I was lucky enough to get my big girl job in a corporate setting – still very focused on sustainability from a health perspective. I put together a sustainability proposal, but soon learned that, in a big organization, only buy-in at the highest level turns an effort into a key initiative. I wasn't senior enough to achieve this and I couldn't make a business case for it yet either.

So, I started tracking my own productivity as a designer — my sales, adoption and sell-through rates, profit margins — and saw steady growth. That’s when I decided to go freelance. My thinking was: if I could do this for 10 companies, I could start proving that cleaner, healthier, lower-impact materials are not just sustainable, but also make good business sense.

mebl: Earlier, you mentioned the importance of data — is there a specific data example that shifted your perspective?

Jerri Hobdy: A real Aha! moment for me was learning about the measurable impact of swapping coconut fiber for polyurethane foam – this was in mebl | Transforming Furniture’s webinar on the Carbon Footprint of Furniture. Prior, I had assumed transportation accounted for the largest share of a product’s carbon footprint, not materials. I think that’s a common misconception.

That insight – that data – really made me rethink material choices. It clicked — of course, the raw materials that go into foam production must have a major impact. That data point was incredibly helpful when I started tackling upholstery fills – they felt like one of the hardest categories to clean up. But seeing that CO₂e reduction made it clear that material selection alone could significantly improve both material health and carbon footprint.

Truly understanding life-cycle assessments (LCAs) and how to measure impact was a turning point in how I approached material decisions — especially in the development of our new collection.

Sofa from Meno Home’s upcoming collection

We also conducted a life cycle assessment on our wood sofa, built with reclaimed ash lumber from CarbonSmart wood. Using their Trace technology, we estimated that our improved sofa without foam at 1.01 metric tons of carbon. It was shocking to see how high the improved number was for the wood frame only!

At the moment, my top two data sources are the Green Science Policy Institute and Sustainable Brands –-- they link out to a ton of research and cite their sources.

mebl: How have these insights on data and impact shaped your new collection?

Jerri Hobdy: I started going through my “rolodex” of manufacturers to see who might be willing to create a commercially scaled collection of cleaner, lower impact furniture with approachable price points.

I landed on a factory in India that I've worked with for a decade. It was the right time in their business. They were willing to build the pieces as specified, help me source new materials and essentially adjust their supply chain. That's no small feat.

We decided to start with some tried and true categories, then looked at what aesthetic would be timely but not too trendy and what materials play into that. We spent a few months chipping away at the ideal, and we were able to achieve it across the board. This collection will include modular and stationary sofas, dining and occasional chairs, consoles, coffee tables and beds -- everything one might need to furnish a good portion of a home.

We have substituted in new materials at every point in their supply chain. We've been able to get all the necessary paperwork and transparency information for environmental product declarations and LCAs.

Now that the products are sampled, physically made and approved for production, gathering all the information, aggregating it, and figuring out how to do and share the calculations is probably the most challenging part of the process.

mebl: Do you feel optimistic?

Jerri Hobdy: I see the last 10 years as baby steps in the big-picture right direction. We don't want to claim that our latest is the perfect collection, but we do feel confident saying this is one of the most sustainable options out there, and here’s how we're going to keep making it better.

--> READ more Changemaker Interviews here.