Changemakers: Moore & Giles x Sustainable Composites

30-Apr-2024

Moore & Giles transfers its leather scraps to Sustainable Composites to upcycle into the Habitat leather product.

“New material adoption represents a big challenge, often a paradigm shift.”

Moore & Giles partners with Sustainable Composites to create a circular material from leather scraps and off-cuts.

Interview #7 in the Changemakers series

How can leather producers play a role in advancing sustainability in the furniture industry? In this interview, we speak to Moore & Giles’ Beverly McAuley – Senior Director of Sustainability & Education – and Sustainable Composites’ CEO Donald Morrison– to learn about their partnership in developing Habitat - a byproduct of a byproduct – a leather composite, made from scrap leather.

In operation for nearly a century, Moore & Giles is a leather producer & retailer based in Central Virginia. With multiple sustainability initiatives, Moore & Giles was searching for a solution to the ‘final part’ of their waste stream when they discovered Sustainable Composites - pioneers in recycling leather from pre-consumer and post-consumer waste.

Like wood and metal, leather is one of the longstanding materials used in furniture design and manufacturing. At the same time, the vegan movement and climate-conscious voices emphasize alternative leathers as more sustainable and humane. In this article, our interviewees raise the question – Which is the more sustainable choice?

This is the 7th in our Changemakers series – interviews with leaders in sustainable, circular and regenerative approaches in the furniture industry. Our aim is to uncover the nuts and bolts of how each leader is driving change, the potential it holds, and why it matters to the industry.

Left: Beverly McAuley Moore & Giles

Top Right: Beverly McAuley; Bottom Right: Donald Morrison, Sustainable Composites

mebl: Tell us about Moore & Giles and your sustainability ethos and offerings?

Beverly: We are a leather company in operation since 1933. We have two business segments – wholesale, which supplies leather to the hospitality, aviation, and furniture industries. And retail, through which we make and sell lifestyle products like accessories, handbags, and furniture.

Leather is circular, in and of itself - it’s a byproduct of the meat industry. For centuries, the leather industry has diverted hides from landfill, turning wasted hides into a useful resource - leather. We are the street sweepers of the meat industry.

We offer two types of carbon-neutral leather that are used for upholstery, furniture, bags, and accessories all over the world. We have over 51 leathers that are Clean Air Gold certified and more than 25 that are Red List Free certified.

Our newest sustainability offering is our Habitat product – produced in collaboration with Sustainable Composites. Through this collaboration, we have taken responsibility for the leather scraps from our manufacturing – by partnering to turn our ‘waste’ into a resource.

Another example of our approach to sustainability is our use of fallen olive leaves – a byproduct of olive production -- to tan one of our leathers. It’s similar to brewing tea! The leaves are processed to create a 100% organic, mineral-free extract that produces a broad spectrum of colors.

At a more operational level, we recently switched our headquarters to solar energy; we’re upgrading to more energy-efficient equipment; and we’ve started transforming our corporate landscape into nearly three acres of native meadow to act as a carbon sink and increase biodiversity.

Moore & Giles’ carbon-neutral leathers - Mont Blanc and Tribeca - on three of their stools.

mebl: Explain what you mean by carbon-neutral leather.

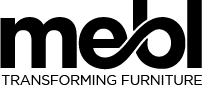

Beverly: We first measured the cradle-to-gate embodied carbon associated with leather, from the upstream processes from the meat industry’s farming, breeding, transportation and abattoir - through core processes of tanning, leather production to packaging. We worked with our tanneries for almost two years to collect multiple Life Cycle Assessments (LCAs).

Once we had the data on our impact, we implemented methods of reducing it. The tannery that we work with on these two leathers switched to solar power in addition to their other carbon emission- and waste-reduction efforts.

We calculated our total impact, subtracted the reduction from switching to solar, and worked with a 3rd party consultant to find a meaningful verified offset project to support for what was left. These offsets now protect an area in the Amazon rainforest – with over 300 species – from deforestation due to cattle ranching.

We willfully decided to make our two top-selling products carbon-neutral. We could have chosen less popular products – with smaller investments, and less significant impact – but we wanted to jump in with both feet. We pre-purchased the offsets based on the sales history of our top sellers - it’s a risk we took.

mebl: Tell us about Moore & Giles’ new Habitat product, and how that came about?

Beverly: Several years ago we started looking at our waste streams. At the time, we were handing over our leather scraps to nonprofits and smaller businesses that make products like earrings and other small goods. Although these are great initiatives, we wanted to find a more circular solution for our off-cuts that would be sustainable in the long run. We wanted to close the loop on our value chain, and find a market for that ‘last piece’ - our scraps.

I came across Sustainable Composites at a Sustainable Furnishings Council working group meeting. I asked how their process is different from bonded* leathers on the market. From our perspective, many companies making alternatives to leather are trying to replace a product that is already a sustainable solution. Studies have proven that the alternatives on the market, including plant-based substitutes like mushroom and cactus ‘leather,’ aren’t as durable. So many producers add plastics or other materials to increase durability. At Moore & Giles, our focus is on material innovation that drives sustainability and produces solutions.

* Bonded leathers are a material made from leather scraps and fibers, and mixed with a binding agent – often rubber or polyurethane – and bound to a backer for support.

Moore & Giles’ Environmental Product Declaration (EPD) – for Aniline / Finished Leather – shows that upstream impacts such as farming and cattle breeding contribute most significantly to Global Warming Potential (GWP) rather than leather production.

mebl: The textile industry is notoriously known for wastewater and chemical run-off polluting the environment. Is leather production really sustainable?

Beverly: Yes, we really think so.. If you look at the Environmental Product Declaration (EPD) of our Aniline Finished Leather, you’ll see that the upstream impacts are by far the biggest portion of the total impacts associated with leather production. That’s the farming, breeding and life of the cow; and the processes involved in the meat production - prior to the leather industry receiving the hide.

If, as in our case, hides are salvaged from the meat industry, there’s a big reduction in impacts. In addition, most of the tanneries we work with recycle 100% of their water. In fact, their filtration systems are so sophisticated that the water leaving the building is cleaner than water coming from the tap. Modern tanneries are a lot more efficient and climate-positive than made out to be by some alternative materials suppliers.

Most European tanneries have to abide by strict regulations and guidelines when it comes to chemicals. They have to be REACH compliant and many are Zero Discharge of Hazardous Chemicals (ZDHC) compliant to operate and trade. And for non-European tanneries that aren’t as closely monitored, we have labels like Declare that help us measure and regulate.

Then, there are other efficiencies – like using fresh hides, instead of salted hides – to reduce the amount of water and chemicals needed to tan. We use all of these methods to reduce our impacts to a minimum.

mebl: Now over to you, Don! What is Sustainable Composites and what’s your role in Moore & Giles’ Habitat product?

Don: Sustainable Composites was founded in 2013. We invented a technology that transforms scrap leather into an upcycled leather material. We grind scrap leather in such a way that the integrity of the original leather fibers are kept intact. This material can be pigmented, embossed or finished like any other leather -- and we think the end product is pretty indistinguishable.

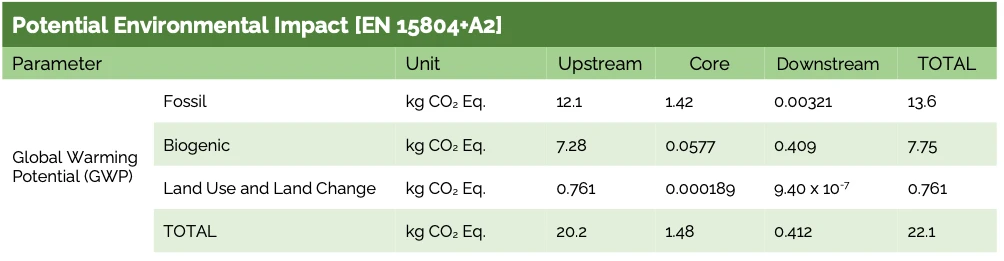

Habitat is Moore & Giles’ version of our upcycled CSR Enspire Leather offering. We partner with companies like Moore & Giles that are looking for a solution for their in-house scrap leather and we manufacture a custom material for them. We take their ‘waste,’ shred it, process it on our specialty machines, and then return the material to them in sheets.

When you see Moore & Giles’ product, Habitat, you’ll notice speckles of red, blue, and green - depending on the colors of scrap leather in that batch. This version of Habitat keeps the leather natural, leaving the ‘crust’ or the ‘base’ exposed to showcase the bare qualities of the material. Habitat sheets can also be refinished and repurposed in most applications as traditional leather and are virtually indistinguishable.

Moore & Giles’ Habitat material is produced from scrap leather by Sustainable Composites. At right, Moore & Giles experiment with upholstering a chair with an original-color speckled version of Habitat.

mebl: What else does Sustainable Composites make?

Don: Our first product that went to market was made out of scrap leather from a Wilson football factory. The shoe brand, Timberland, created a line of three men’s boots and one women’s boot from our material. Another focal point is our post-consumer offering. We’ve partnered with a US-based company called ReCircled that takes post-consumer (and pre-consumer) products, disassembles them, and finds alternative uses for the materials to keep them out of landfill. We’ve also started engaging with some luxury brands about creating custom solutions for them from post-consumer materials.

mebl: What makes Sustainable Composites’ process more sustainable?

Don: As Beverly mentioned, the leather industry has been using meat industry ‘waste’ for centuries - transforming animal hides that would otherwise be dumped into high-end leather products. And, even still, up to 50% of all leather ends up as waste. One reason is that a hide – traditionally from cows, pigs, or sheep – is irregularly shaped. It’s often impossible to use the entire hide when cutting patterns. At present, about 4 billion pounds of scrap leather gets landfilled or incinerated. Incineration generates CO2, and landfilling creates methane that is 80x more harmful to the environment. Most scrap is landfilled.

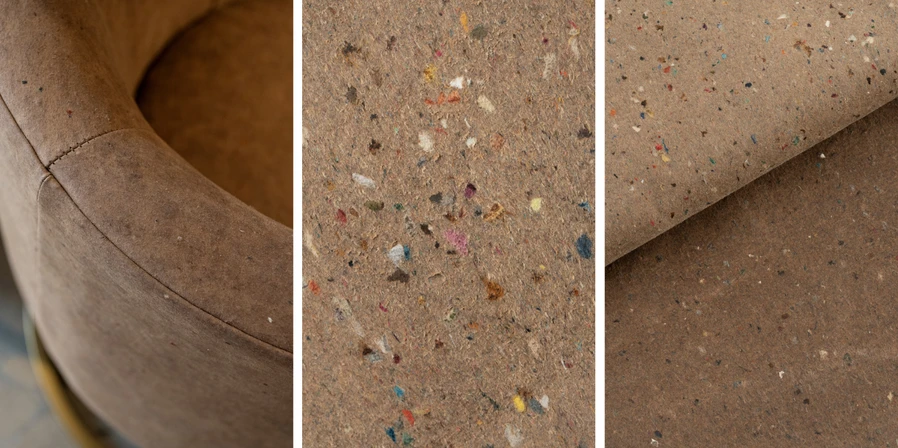

Our upcycled leather, by contrast, comes in 54”- wide rectangular sheets or rolls which allow for more accurate pattern making and thus reduces waste. Our upcycling – including the Cutting Room Scraps process used for Habitat leather – generates 75% less carbon than traditional leather production**. We had a third-party company do an LCA comparing the two processes.

One suggestion we make to brands is to create a ‘line within a line’ of recycled products (like Habitat), which we believe will appeal to a younger demographic and create a new customer base for the future. Because customers’ perceived value of products utilizing recycled material is yet to be determined, we suggest that companies – rather than jeopardizing flagship brands by replacing their current material with an upcycled version – create a collection of products transparently made with recycled leather. And let the market decide!

**The LCA conducted by Moore & Giles, mentioned earlier, suggests that the Global Warming Potential (GPW) of Moore & Giles’ leather is far lower than the ‘conventional leather’ (Higg Leather) shown below.

A Life Cycle Assessment (LCA) completed for Sustainable Composites compares the Global Warming Potential (GWP) of the company’s upcycled Enspire leather with the GWP of conventional leather.

mebl: What has been the biggest challenge in getting your Enspire product to market?

Don: Adoption of a new material is one of the biggest challenges in the marketplace. It requires a paradigm shift at many levels. I’ve come across many product managers who are reluctant to add a recycled material to their line because they're worried about their typical consumer’s perception of value.

That’s why partnership is so important. To be successful, we must partner with great brands like Moore & Giles who are truly committed to sustainability and circularity. We must combine our strengths to introduce this new innovation to the market. For an effective partnership, it takes leadership, great communication, the ability to understand each other's goals, and working jointly towards a solution that benefits both the companies and the planet.

The Puzzle Chair by Leather Miracles is another recent example of a successful collaboration. Exhibiting it at the High Point Furniture Market stimulated great conversations with many senior furniture executives about the challenges of leather scrap disposal. For this, I’m eternally appreciative of the CEO of Moore & Giles, and others, as early supporters of our upcycling technology.

Puzzle Chair by Leather Miracles, upholstered with Sustainable Composites’ upcycled leather, on display at the High Point Furniture Market in North Carolina in April 2024.

mebl: Don mentioned the challenge of shifting paradigms. To both of you - How do you approach shifting perception at an organizational level within your companies?

Beverly: I have great support at Moore & Giles. In order to get everyone in your organization to believe in what you do, you have to place sustainability at the center – and you’ll need the support from the top down. I stepped into my position with a keen passion for sustainability, but it took the participation of the CEO and the company president to help shape what I do and kick it into full gear.

Don: I back Beverly on this. Positive change at an organizational level needs to come from the top to be most effective. This is where a CEO’s vision and commitment to sustainability are essential.

mebl: Don, from your perspective, what would you advise furniture companies that want to go up the sustainability curve?

Don: If I were the CEO of a furniture brand, I would focus on creating a collection of uniquely recycled furniture. I'd use reclaimed wood for the frames, recycled fabrics - and of course Enspire Leather - for the upholstery. Historically, furniture sales purely depended on design and price. Today, more and more consumers are asking questions about the materials and the carbon footprint. Using recycled materials to produce furniture provides a great story - that appeals to a whole new audience. It’s a way to expand your base, increase sales, and gain more customers for the future.

mebl: Beverly, what would be your final word of advice for sustainability champions in the furniture industry?

Beverly: Divert from landfill! Landfills are the third largest source of methane in the US, and methane can cause far more damage than carbon dioxide. To combat this, at a very basic level, designers and brands should create furniture that is useful, durable and outlasts the other options on the market. Additionally, brands must avoid virgin materials and use recycled materials where possible. The less product goes to landfill, the better!

And then of course, I would encourage brands to invest in certifications and transparency. Applying for labels helps measure your impact and forces you to look at regulations around chemicals, waste, and their relation to your state or country. Understanding your impact is important!

-

As resources on the sustainability of leather, Moores & Giles recommends:

READ more Changemaker Interviews here.