RETHINKING DESIGN: Embracing Circular Economy Principles

11-Sep-2024

Photo Courtesy of Uhuru Design

RETHINKING DESIGN:

How furniture companies are embracing circular economy principles

Our first article in the series “Furniture and Circularity: A Primer” introduces the circular economy as an alternative to our current wasteful economic system. At present, our linear economy model follows the “take-make-use-waste" credo, in which raw materials are extracted from the earth, transformed into products, used, and ultimately discarded.

This wasteful process, however, isn’t inevitable. “Waste and pollution are actually the result of design choices, ”the Ellen MacArthur Foundation notes, going on to demonstrate that 80% of a product’s environmental impact is determined during the design phase. The circular economy aims to reframe this “inevitability” by placing design at the center of both the problem and the solution.

Designing Out Waste and Pollution in the Furniture Industry

A core principle of the circular economy is designing to eliminate waste and pollution at every stage of a product's lifecycle — from material extraction and production to shipping and disposal. In the furniture industry, this can involve precision manufacturing to maximize material use, repurposing reclaimed materials, eliminating harmful substances like toxic glues and fire retardants, or rethinking packaging choices.

Durability is another critical aspect of circular design. Products designed to last, like sofas with repairable parts, have a longer lifecycle and can even become heirloom pieces.

Let’s look at some real-life examples to see how furniture designers and brands are tapping into this circular economy principle.

Photo Courtesy of Andreu World

Andreu World by Philippe Starck

By embracing the intelligence of plywood and ancient joinery techniques, Philippe Starck’s designs eliminate the need for nails, screws, and glues by utilizing interlocking parts. This reduces material use.

Starck, a French designer, emphasizes minimalism. "When you speak about nature and ecology,” he explains, “you have to speak about the minimum." Made of 100% FSC-certified wood, Starck’s collection is fully recyclable and Cradle to Cradle® certified, ensuring it can be easily repaired without diminishing its value.

Photo Courtesy of Uhuru Design

Uhuru Design

"We are scrappy by nature," notes Uhuru. "We do more with less." Founded in 2004, Brooklyn-based Uhuru Design gained recognition for its creative use of reclaimed and sustainably harvested wood and metals. As the company expanded into commercial furniture, sustainability remained at its core. Uhuru now utilizes certified sustainable woods and highly recycled metals that are 100% recyclable. Their products are designed for disassembly, making recycling straightforward at the end of a product’s lifecycle.

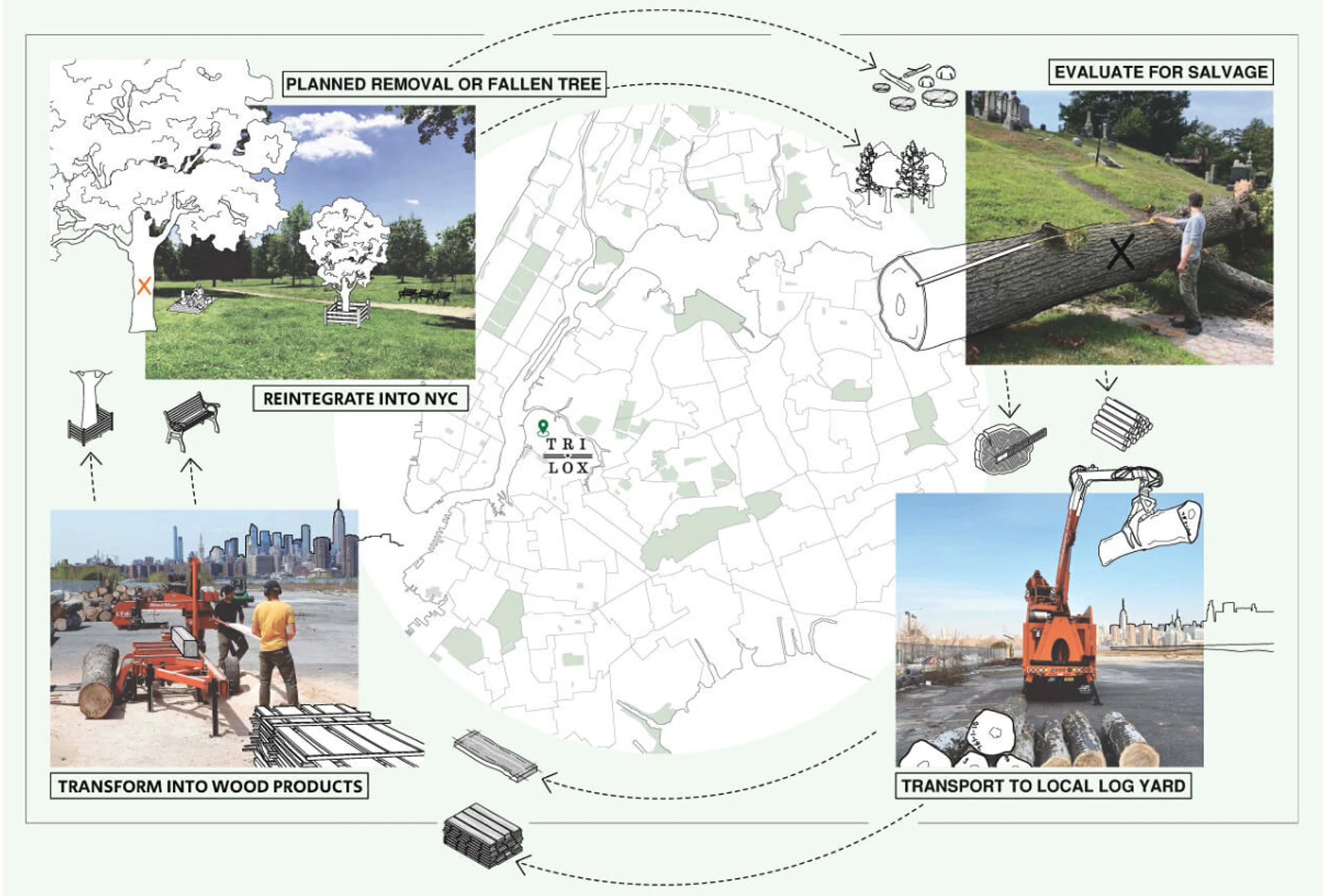

Tri-Lox Circular Wood System

Tri-Lox, another Brooklyn-based firm, is a leader in wood reclamation and regenerative forestry. The company sources from regional forests, deconstructed buildings, and urban trees slated for disposal.

Tri-Lox has processed wood for products and projects such as the Treeline series of lighting fixtures for Stickbulb; dining tables for Danny Meyer’s Shake Shack; and ‘The Last Stand by Kamala Sankaram’ - an installation with a seating system built of reclaimed cedar from deconstructed New York City water towers.

Working with over 130 organizations and government agencies, Tri-Lox is helping expand New York City’s urban forest. “Through research, design, and craft,” explains Tri-Lox, “we are building a circular wood system.”

Photo Courtesy of Moore & Giles

Photo Courtesy of More & Giles

Moore & Giles + Sustainable Composites

Moore & Giles, a nearly century-old leather producer based in Virginia, exemplifies circularity through its partnership with Sustainable Composites. This collaboration turns leather waste from pre- and post-consumer sources into new products, transforming what was once discarded into a valuable resource.

Additionally, Moore & Giles uses olive leaf extracts, a byproduct of olive production, to tan leather organically, offering a sustainable alternative to traditional methods. On the operational front, Moore & Giles has transitioned to solar energy, invested in energy-efficient equipment, and converted three acres of its corporate landscape into a native meadow to enhance biodiversity and act as a carbon sink.

Steelcase

Steelcase is embracing circularity by rethinking its design processes, from finishes to packaging. By collaborating with paint supplier PPG, Steelcase is now reclaiming and re-using powder coat paint, reducing waste by 91% — a recovery of 97,000 pounds of paint annually.

Steelcase's ‘Hack the Pack’ workshop led to packaging redesigns, such as replacing foam with recyclable cardboard for Steelcase’s Vern table, eliminating 73,000 pounds of styrofoam waste each year. This also reduces shipping needs.

In an industry such as furniture design, a great deal of waste and pollution can be mitigated through intentional design choices. By embracing principles of the circular economy, companies are designing durable, reusable and recyclable furniture – significantly reducing their carbon footprint by lowering greenhouse gas emissions associated with resource extraction, manufacturing and disposal. This ultimately helps to mitigate climate change. The circular economy offers a promising alternative to the traditional linear economy.

READ other articles in the series - Furniture and Circularity: A Primer.